But be careful! Plenty of stuff down this list that can severely hurt you, or even kill you. I’m certainly not a trained professional. Please try anything you see me do at home. If you would like to have them before I get around to this, send me a mail at I will try to get them to you. The post processing python scripts are not “consumer ready” 🙂 I will try to make them a bit more user friendly and add them here for download at some point. Some “in house” python scripts for mask bitmap processing.UV exposure unit with a built in vacuum system.In most cases the result will be just as good without them, it will only be a bit more time consuming.

But don’t despair if you don’t have them. And they do make the process quicker and easier. But then again, I have only made 1 attempt. 8-mil and up seems to give plenty of headroom, but 6-mil might not give a 100% yield.

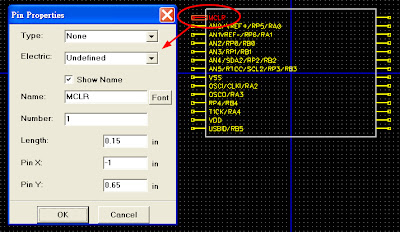

I partly did this to be able to fit 2 traces between the pins of one of the connectors, but mostly to see if my DIY skills and equipment where up to it 🙂 I try to not go smaller than 8-mil unless absolutely needed. There is however a small section where 6-mil traces with 5-mil spacing is used successfully. And most of the spacing is 8-mil or more. Most of the signal traces on the PCB is 10-mil, and most of the power traces are 15mil. Very useful when prototyping with one of those MCUs before making a dedicated PCB. It holds the MCU plus a 20MHz crystal, a voltage regulator, an ISP socket, a power socket, and a signal socket that expose all IO lines from the MCU. The PCB I create in this guide is a tiny breakout board for the ATmega88/ATmega168/ATmega328 series of microcontroller. Creating a double sided PCB with solder mask

0 kommentar(er)

0 kommentar(er)